Description

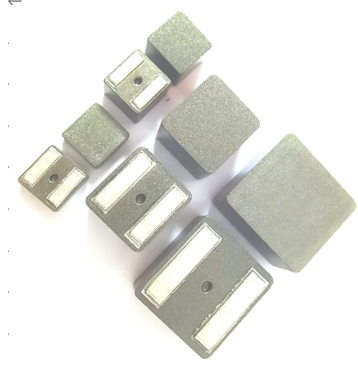

Composite injection mold inductor

Composite injection mold inductor

Features

Excellent current handing

Exceptionally low DCR

Soft saturation

Composite construction minimizes audible buzzing.

Tin silver over copper terminations

Composite material.

Excellent current handing

Exceptionally low DCR

Soft saturation

Composite construction minimizes audible buzzing.

Tin silver over copper terminations

Composite material.

Applications

Perfect for VRM /VRD applications.

Perfect for VRM /VRD applications.

| Test Voltage | 1.0V |

| Parameters Test Temp | 25°C |

| Operation Temp (Incl temp rise) | -40°C to +125°C |

| Storage Temp | 0 to 40°C |

| Storage Humidity | 10% to 70% RH |

| Resistance to Soldering Heat | 260°C for 10 sec |

| Rated Current | L drops off 30% typ at Isat |

| Temperature Rise | 40°C typ. at Irms |

OWIHPM0630-R56

Composite injection moldedAll in series

Product ID

Inductance

DCR [mOhm]

Isat [A]

Irms [A]

Irated [mA]

Idc max [mA]

Q (min)

SRF [MHz]

Samples

Inductors:

Product ID

OWIHPM0630-R56

Inductance

0.56 uH

DCR max:

3.50

IsatA table:

29.00

Irms A table

21.60

Custom 1:

Custom 2:

Q min:

SRF [MHz] min:

samples visning

L tol note:

When ordering please specify tolerance code Tolerance: N=±30%, P=±25%, M=±20%

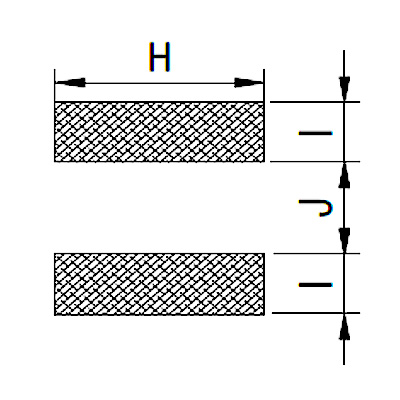

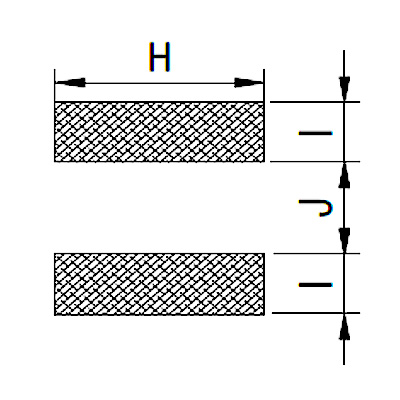

Shape and dimensions [mm]

A

B

C

D

E

F

G

H

I

J

Shape

A:

6.60

A tol:

±0.20

B:

6.40

B tol:

±0.20

C:

2.80

C tol:

±0.20

D:

TBD

D tol:

±0.30

E:

1,4

E tol:

±0.30

F:

2,6

F tol:

±0.30

G:

G tol:

H:

5,6

H tol:

Ref

I:

1,56

I tol:

Ref

J:

2,5

J tol:

Ref

Shape:

Square

Dimension remarks:

Dimensions Image:

PAD Image:

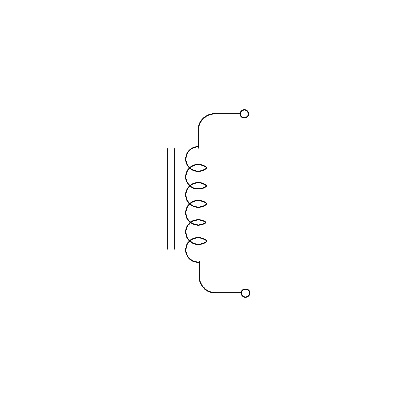

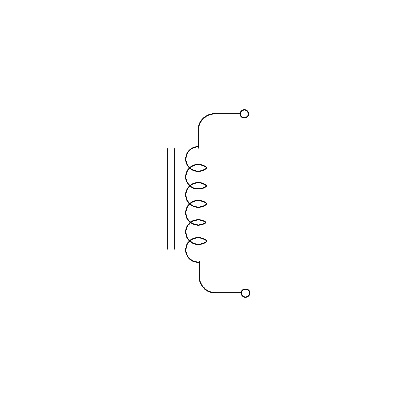

Schematic Image:

click images to enlarge

Ole Wolff Elektronik A/S

|

Roedengvej 14, 4180 Soroe, DK Denmark

|

+45 5783 3830

|

sales@owolff.com